It’s important to keep your system up and running without regular intervention. While every system requires maintenance, never overlook the critical importance of tools and training for the operators.

Once an automation system is up and running, it’s crucial to ensure it continues running smoothly with minimal effort on your part.

While it’s never a bad thing to take pride in a successful system you’ve created, you should aim to maintain a hands-off approach. Therefore, you need a system in place to manage your new installation. In this article, we will discuss the importance of having reliable work instructions, a training method for the operators, and a maintenance schedule for each component of your automated cell.

Figure 1. Performing maintenance on machines.

You Need Instructions BEFORE You Can Train

If you don’t know already, then trust me when I say this: the paperwork side of things can be extremely boring and tedious, but it will make your job so much easier. So, what are work instructions and why are they important?

Work instructions provide a visual representation for operators, trainers, maintenance personnel, and engineers of any tasks that need to be performed.

For example, work instructions on the operator level might include:

- Preventative Maintenance – separate by daily, weekly, monthly, and yearly

- Powering the Machine ON

- Loading a Program

- Changing Tooling

- Starting a Cycle

- Shutting the Machine Down

Now some of you may read this list and think, “Really? You need to explain the process for powering a machine ON and OFF?” Yes, there needs to be a procedure for everything! It also needs to be written in a way that everyone can understand.

As the local expert in the initial design of the automation system, it’s your job to keep everyone safe and allow everyone to understand what you’re saying. My recommendation is to try and break down your work instructions in ‘Barney’ style.

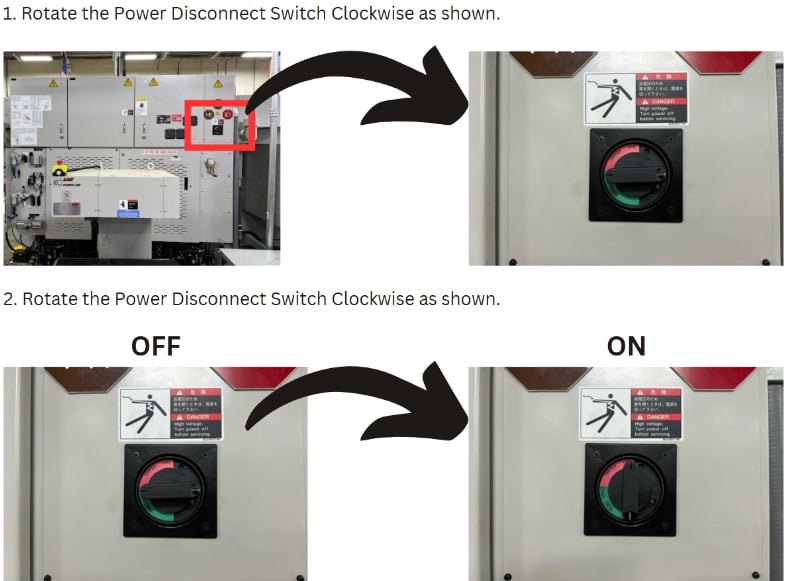

Figure 2. Image is used to depict a simple and easy-to-understand instruction set.

Please ensure that work instructions are clear and brief. If you find yourself frequently being asked about a specific task, please develop a work instruction for it. Make the instructions easily accessible and place them as close to the machine as possible. This can be accomplished by using a three-ring binder with tabs for each task, keeping a laptop or desktop computer nearby with the instructions loaded, or having the instructions readily available in your HMI.

Training is an Ongoing Task

Employees in the operation, maintenance, and engineering departments may change for various reasons, making it virtually impossible to rely on the training of one individual forever. However, with comprehensive work instructions, training new personnel becomes more manageable. During training sessions, ensure that each trainee has a copy of the instructions to refer to instead of constantly seeking guidance from you. This way, they can consult their references independently.

To ensure consistency, I prefer to conduct training in the same manner each time. I usually begin in a meeting room or classroom setting, where I present a PowerPoint of the work instructions I will be training the personnel on. Depending on the complexity and relevance, I cover 2-3 work instructions and then proceed to the work floor to have them carry out the tasks. I ensure that everyone performs the tasks on the floor. This approach helps avoid the monotony of overreliance on PowerPoint presentations, as anything over 20 minutes of PowerPoint is excessive.

Please make sure to keep the following information in mind:

The final part of the training process is the documentation. At the conclusion of each training session, the individuals who have undergone the training will need to either sign documents confirming their participation in the class, or they may be asked to take a brief test to assess their understanding of the material. If the training process is straightforward, it is preferable to have them sign the documents rather than take a test. However, if the training is complex or if safety is a concern, it is advisable to have them take a test in order to ensure that the training has been effectively absorbed. Depending on your or your company’s policies, it’s important to consider conducting regular supplementary training sessions to make sure that everyone remains well-informed.

You Can’t Run Forever, and Neither Can Your Machines

No matter the quality of the machine’s design, eventually, maintenance will be required. Depending on your system, batteries may need to be replaced, filters will need to be cleaned or changed, grease and lubricants will need to be added, or mechanical components need to be replaced.

Figure 3. Maintenance Personnel performing a regular maintenance service.

In order to prevent unnecessary downtime with your automated equipment, it is necessary to create a regular preventative maintenance schedule.

BACKUP BACKUP BACKUP

Always start with the most important tasks, such as creating backups, as they are mandatory. As an automation expert, you should establish a schedule for backing up your system, whether it’s on a monthly, quarterly, yearly, or any other interval that you consider necessary. Make sure to back up PLCs, robots, drives, and any other devices to prevent major issues in the future. You can always buy exact replacement hardware, but no money can purchase the program that was stored in the old device.

Batteries

Remember to pay attention to certain components that are easy to forget about but can cause major problems if neglected. Many devices, such as PLCs and robots, have batteries that need to be replaced regularly, and there may be more than one. For instance, some FANUC robots have batteries for the servos and a separate one for the controller. Always follow the manufacturer’s guidelines for replacing batteries and make sure to have backups in case the batteries fail, as failure can result in costly downtime and extra work.

Regularly Scheduled Maintenance

Make sure to prioritize production in a manufacturing environment, but don’t neglect the regular maintenance of your machines. Neglecting maintenance can lead to downtime, even if the machines are currently running smoothly. Collaborate with your maintenance department to ensure that your systems are consistently maintained.

Depending on the system, maintenance work requests may be submitted digitally or scheduled. You can always use visual devices like HMIs, work logs, or cloud-based dashboard tools to confirm that maintenance is being carried out as scheduled.

Copyright Statement: The content of this website is intended for personal learning purposes only. If it infringes upon your copyright, please contact us for removal. Email: [email protected]