If your facility or workplace uses a PLC, it’s almost certainly because it must interface with physical input and output devices. What kinds of I/O modules exist, and how can you tell the difference?

Out of all the sub-system components that make up a PLC, and throughout the world of computers in general, the I/O modules are usually the most immediately embraced by engineers who enjoy the physical realm of devices and wiring.

That’s not to say that it’s simple or easy; in fact, it can be one of the most confusing parts of a plc, but the I/O modules represent the connection interface between digital computation and real-world input and output devices.

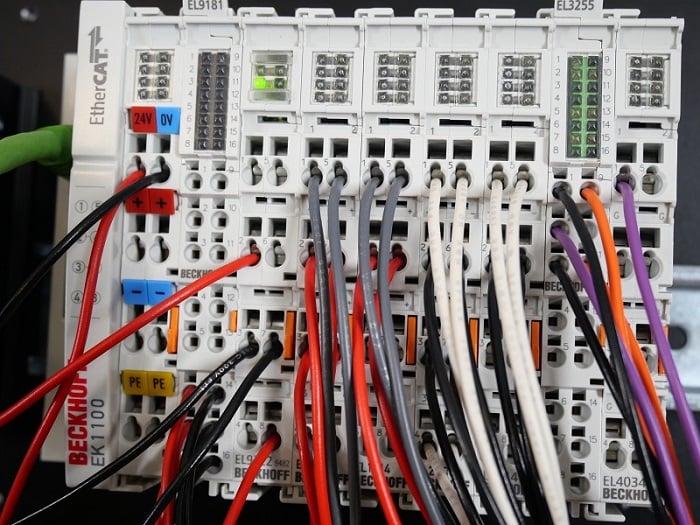

Figure 1. A wide variety of I/O modules in one unit.

What Can I Connect to a PLC I/O Module?

We’ll cover the many types of modules shortly, but first, it’s important to understand what kinds of things you can connect to a PLC in this way. Surely, you can’t just hook everything up to a PLC and expect them to work, can you?

First, the category of inputs is pretty broad. If a switch or pushbutton has mechanical contacts, then yes, you can connect virtually any of them to a PLC, providing that you can somehow connect a wire to either side of the contact. You could theoretically connect anything from a massive disconnect switch down to a tiny tactile surface-mount PCB switch. Although we mainly find buttons and switches in the 22 mm category, designed for ease of use for industrial enclosures.

Sensors often have a solid-state construction, so they can only provide one kind of voltage output. If the sensor is designed for 10-30 VDC or 120 VAC, then it’s perfect for a PLC. Some sensors are made for 5 volts. To use these, you either need a special low-voltage input or a way to amplify the output up to 12-24 volts.

The types of outputs, or loads, are also quite broad. If something can be switched ON and OFF, then it’s likely also fair game for a PLC. Common items are lights, relays, solenoid switches, and valves. The voltage rating of the device doesn’t really matter since output modules can handle virtually any voltage. If the device runs from a pulsed output, like a motor drive, or even a variable signal (like volume or speed), then we can probably find an appropriate PLC output.

PLC Input Module Types

Here is a short selection of the most common PLC input module types. Some companies may manufacture specialized modules that do not appear on this list.

DC

DC input modules respond to a limited range of voltage, usually 12-24 or only 24 volts. They can be sourcing or sinking (more on that topic), and the number of terminals on a single module can vary from 4 all the way to 32 in some high-density models. These are widely used for switches and sensors.

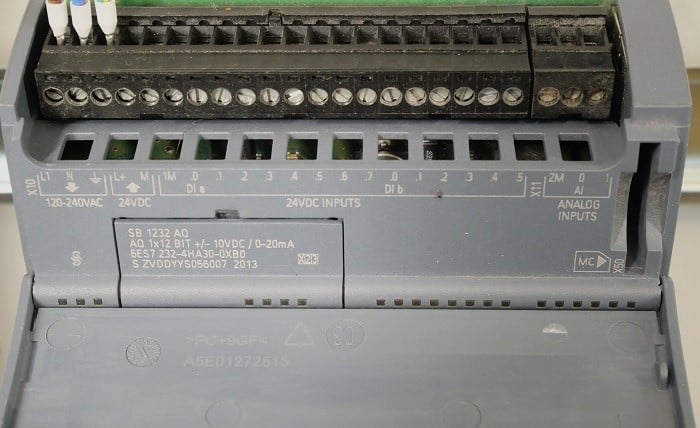

Figure 2. The high-density connections from a 32-input module.

Analog

Analog inputs can be voltage (0-10 volts, usually), current (4-20 mA, usually), or configurable to work either way. They can provide isolated inputs or return to a common ground, so it’s important to work with experts in the field of signal integrity to know exactly which variation is best. The number of input terminals ranges from 2 to 8, usually no more.

Figure 3. Analog inputs alongside DC inputs.

AC

Many switches and sensors handle AC voltage, just like the light switches in your home. It would be expensive to convert each signal to a 24-volt DC output, so the solution is an input module for 120 VAC signals. These modules require one common neutral connection, never opting for the sourcing style of input, which places a live 120 volts on each terminal. Sometimes models are available for 24 or 240 VAC, but the most common is 120 VAC. This type is usually found with between 8 and 16 terminals.

High-Speed

These are a variation of the DC inputs, only optimized to accept rapid input pulses. The two most common device types for this module are high-speed encoders and external controllers that deliver a pulse-width (PWM) or pulse train output signal that must be accurately measured. In most cases, a high-speed input can still accept standard DC inputs with no problem. These commonly contain fewer inputs, with between 2-4 common on a single module.

TTL

This acronym stands for transistor-transistor logic, but in simple terms, it means that 3.3 to 5-volt devices that are usually reserved for embedded computing and microcontroller applications. The most common reasons for requiring such a module are interfacing with the digital I/O of such an embedded computer in a peripheral device. In most modern technology, this is replaced by a communication protocol or a level-shifter, so the TTL input is a fairly uncommon module type in modern PLCs. They can have around 8 to 16 terminals.

PLC Output Module Types

Output signals are quite similar to inputs, except the PLC emits the signal. But not everything is identical.

DC Output

This is almost the same as the description for DC inputs. This module typically powers 24-volt devices, and they can be found in both sourcing and sinking types with between 4 and 32 terminals.

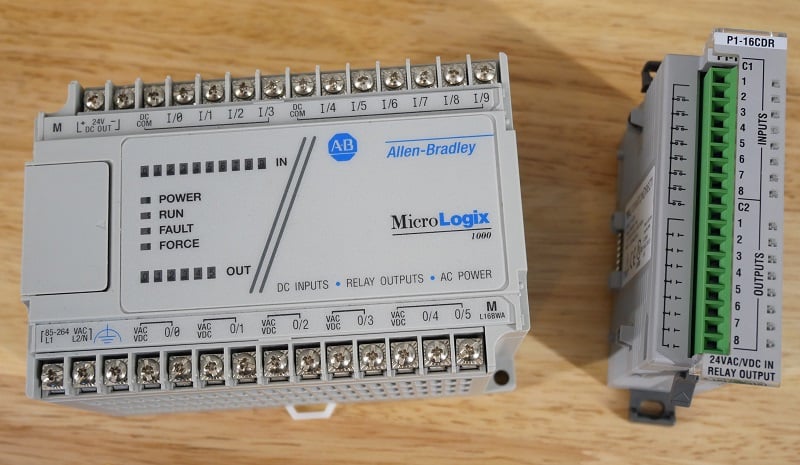

Figure 4. Relay outputs in the same unit as digital inputs–they can mix-and-match!

Relay Output

Relays are very flexible since they can handle various voltages (DC and AC). They are slower to respond than DC outputs, and they don’t last as long, but they can handle far more current. Some modules only provide the N.O. output (form A), but some provide access to both the N.O. and N.C. (form C). There are typically between 4 and 16 terminals in a relay output.

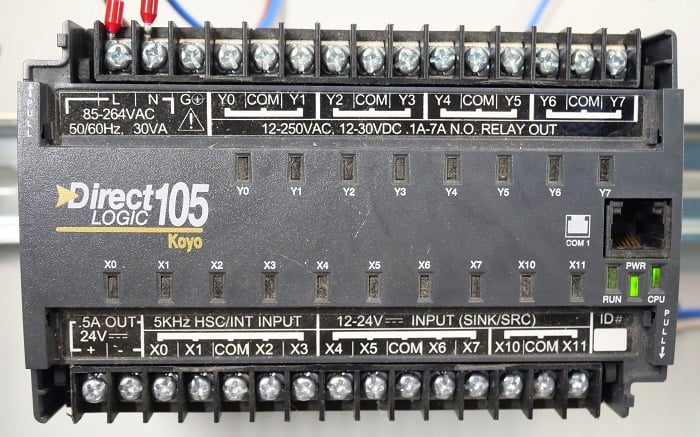

Figure 5. Numerous I/Os: 8x relay outputs (form A), 6x DC inputs, and 4x high-speed inputs (which can also be standard inputs) all in one PLC.

Analog Output

As with the inputs, analog outputs can deliver voltage or current sources. Since most inter-device signals are sent over a communication protocol, analog outputs aren’t as common as inputs. These modules have between 2 and 8 terminals.

AC (TRIAC) Output

While relay modules can handle some AC loads, any switching that requires high speeds and a long service life still needs a solid-state switch. The TRIAC is the powering device inside the AC output, and they are usually limited to 120 VAC loads. (Troubleshooting can be tricky: explanation here). These typically range from 8 to 16 output terminals.

Custom I/O Modules

The above descriptions include a major majority of all the modules used in running systems today. Be aware that nearly anyone can create a custom module, so you may run across models with slight variations or an entirely new type of module. Just pay attention to the tech details, follow the wiring diagrams, and learn as much as you can from the current engineers in case you find yourself in charge one of these days!

All images used courtesy of the author

Copyright Statement: The content of this website is intended for personal learning purposes only. If it infringes upon your copyright, please contact us for removal. Email: [email protected]