There are a lot of companies considering in-house automation or consulting with integrators for automated systems. But where do you start, and how do you even pick a project for automation?

One of the most impressive things in the manufacturing world is when products are being made with little or no intervention, giving operators more time to inspect for quality defects or improve other parts of the process. It may seem as though operators are nowhere near the machine, but trust me, they are.

The dream might be to have everything running completely autonomously, but let’s be realistic, it’s probably not going to happen.

There are plenty of companies that will admit that they have little to no automation, but they don’t have the capital to hire an automation company or the resources to automate for themselves. There are also very few resources on how to get started with in-house automation. So let’s start with the basics. How do you pick a project for automation?

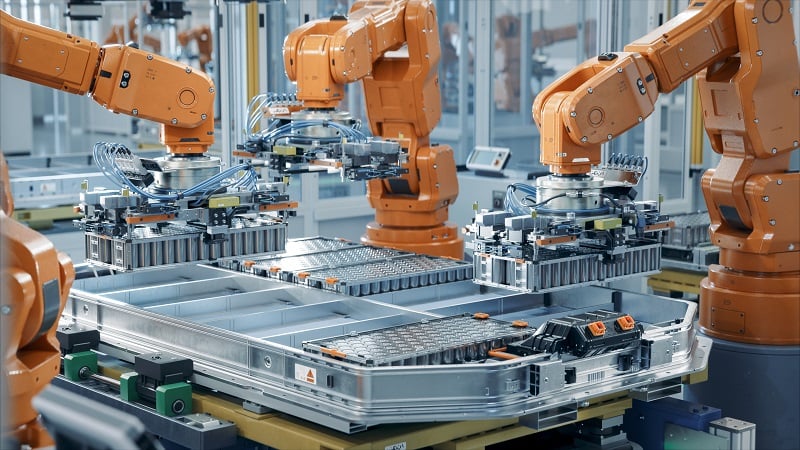

Figure 1. Robots assembling consistent, repeatable, and heavy parts into a frame: a perfect candidate for automation.

Everyone’s Got Ideas, But What’s the Right One?

If you have worked in manufacturing for even a short time, you’ve probably thought, “this should be automated” at least once or twice. The question is: does it make sense to automate?

Let’s begin by talking about the goals for automation. Typically, any automation project will be driven by one or more of the following goals:

- Maximizing Return on Investment (ROI): This is typically the biggest driving factor and will be a major factor in management decisions about automation projects.

- Capacity vs. Projected Volume Growth: It doesn’t matter what you make, there will only be a certain time capacity for production, but reducing bottlenecks and increasing throughput can allow businesses to sell more products to meet demand.

- Reducing Labor Costs: This is one of the most controversial factors and creates the most fear among workers. However, a plant cannot run without laborers, but improving man-to-machine ratios and increasing efficiencies allow more products to go to the customer with fewer costs.

- Dangers in the Workplace: There are many manufacturing processes out there that are just too dangerous for people to work around due to extreme temperatures, radiation, exposure to dangerous chemicals, risk of loss of life or limb, etc.

- Quality Control: While humans can detect a variety of defects, the human eye is, unfortunately, limited in speed and may not be able to keep up with the demand necessary.

As an engineer, we all have our own areas of expertise throughout a plant. Some will specialize in assembly processes, CNC, injection molding, heat treatment, etc, but all areas throughout the plant have something that can be automated. But this does not mean that everything can or should be automated! So let’s take a look at one of the more commonly automated applications: machine tending.

Machine Tending Applications

For automating machine tending applications, we’ll discuss three generic CNC cases for turning components.

Figure 2. Machine tending application. A Fanuc M20iD tends to a Haas Vf2ss lathe.

- Volume per year is 50,000 pieces (10 lots/year @ 5000 pcs/lot).

- The manual cycle time for OP10 is 2 minutes. (cycle start to cycle start).

- The manual cycle time for OP20 is 1 minute. (cycle start to cycle start).

- Forging has been faced on both sides and contains no burrs.

- Surface finish and tolerancing allow for proper depths of cut to generate a proper chip.

- Due to machine layout, the current man : machine ratio is 1:1.

Details of the application 2: Bandsaw cut ring.

- Volume per year is 50,000 pieces (10 lots/year @ 5000 pcs/lot).

- The manual cycle time for OP10 is 2 minutes. (cycle start to cycle start).

- The manual cycle time for OP20 is 1 minute. (cycle start to cycle start).

- The ring is presented to the operation still covered in chips from the bandsaw and one face formed a large burr while being cut on the bandsaw.

- Surface finish and tolerancing will force constant monitoring and finish pass causes a stringer to be formed.

- Due to machine layout: the current man : machine ratio is 1:2. Due to cycle time, efficiencies are lost.

Details of the application 3: Boring the Inner diameter of a rod end.

- Volume per year is 500 pieces (1 lot/year).

- The manual cycle time for OP10 is 4 minutes. (cycle start to cycle start).

- Rod end is a clean cast forging.

- Due to machine layout, the current man : machine ratio is 1:2. Typically partnered with another random part number.

Let’s start by discussing the details that would make each of these applications ideal or not ideal for automation. Even though we are only discussing a machine-tending application these ideals can be related to any process being considered for automation.

Volume: Let’s be honest, if the machines aren’t running, there’s no way you’re making money. The ideal scenario is to be running all year long non-stop, but that’s not realistic. Machines need to have preventative and scheduled maintenance throughout the year and you’ll probably have set-ups on other components as well. From my experience, if there is a plan to run for roughly 50-60% of the year with an expansion plan, that is an ideal starting point.

The volume of each part in applications 1 & 2 allows one machine to run for roughly 1700 hours for OP10 and 850 hours for OP20. Under the assumption that each operation runs on a different machine that allows for the part to be run at roughly a 90% efficiency for one shift for 1 year for OP10, and one shift for six months for OP 20, however, the volume for application 3 only utilizes one machine for 67 hours making application 3 less ideal for volume.

Repeatability: Automation requires parts to be presented to the system in the same orientation. An operator can identify issues when loading a part into a CNC while a robot or automation equipment can’t identify these issues. If you cannot repeatably do this manually without making a single change, it is not ideal.

In applications 1 and 3, this can be achieved. Due to the shape of the parts, cleanliness, and reliable size of the forgings, the parts can be presented in a way that allows for a repeatable setup. In application 2, the rings presented are covered in chips, meaning the part may still be picked up, but when loaded into the machine, the chips will most likely cause misloading leading to quality issues or even damage to the machine or danger for the operator. Either fix the chip issue before the process or move to a more realistic project.

Quality Control: When determining if a process will be good for automation, truly watch the process. If an operator has to make offsets or changes to the setup more than once or twice an hour, in-process gauging may be required to automate the process. However, the offsets must be predictable. If the changes in quality are random, consider reviewing the process. In this example, all three processes may be automated if the quality conditions are predictable, but there can be hangups with application 2 due to tolerancing.

Added Benefits: With automating any one of the processes, there are some added benefits that I haven’t discussed, such as increasing the man : machine ratio. Reducing unnecessary labor can drastically reduce the cost of running a plant. Without the operator having to manually load and unload machines, quality can be monitored with a reduction of rework or scrap components.

Figure 3. Machine tending application. Automation allows for the loading and unloading of components without the need for an operator to be present.

With CNCs, operators are also exposed to a variety of health concerns, that can lead to extreme costs to the company. Allergies can occur at any time, and one of the most painful that I have seen in the manufacturing world is developing allergies to coolants/oils. This can cause operators extreme discomfort and rashes to break out, causing lost time incidents.

Something we don’t always consider (but should) is the wear and tear to the body from repeated tasks such as opening and closing a CNC door or loading components into the chuck. One of the largest worker’s compensation claims comes from torn rotator cuffs due to repeatedly strained activity on the shoulder.

Project Scope and Project Creep

The last thing that I would like to discuss has been the downfall of many automation companies or in-house projects. Once the scope of the project is defined, components have been ordered, and the layout has been decided on, stick to the scope. Once the planning stage is done, you have to do everything in your power to prevent uncontrolled growth of the project scope. This will lead to complications further down the line that could cause your system to fail or be extremely over budget. You can always return and scale up the project if the ROI is proven.

Automating tasks can significantly enhance efficiency, reduce human error, and free up valuable time. By carefully evaluating the nature of the task, its frequency, and the potential impact on productivity, you can make informed decisions about what to automate. Remember that not all processes are suitable for automation, and a thoughtful approach ensures that automation aligns with your goals and resources.

Copyright Statement: The content of this website is intended for personal learning purposes only. If it infringes upon your copyright, please contact us for removal. Email: [email protected]