Functional safety is the safety of a system and is critical for industries such as medical devices, automotive, railways, and machinery. This article will focus on functional safety for machinery and the standards that help its implementation.

Functional safety is one of the methods to ensure safety in various industries. It does not deal specifically with protective or safety sensors. Instead, it focuses on a broader version of safety implementation techniques to make systems safe for man, machine, and material.

Some industries for which functional safety is critical include medical devices, automotive, railways, and machinery.

Figure 1. Functional Safety ensures safe operation of machinery.

What is Functional Safety?

For a machine, functional safety is defined as the ability of a system to reduce safety risks in the event of electrical, electronics, and software breakdown. When such a breakdown occurs, the machine’s behavior cannot be controlled or predicted and can become hazardous for man, machine, and material.

In simple words, functional safety is ensuring the safe operation of machinery during its entire cycle of operation against all risks.

Functional safety is becoming critical because more and more systems have become automated, and technology is now in the driver’s seat of industrial processes. Functional safety is used to make automated systems for machinery.

The goals of functional safety in machinery are avoiding and controlling recurring faults and avoiding and controlling non-recurring faults

Some ways functional safety is different from normal safety practices:

- Functional safety is implemented in electrical and electronic-related systems, while normal safety practices are implemented for manual systems.

- Functional safety systems automatically react or respond to reduce the hazard. Normal safety practices depend on human involvement to reduce the hazard risk.

- Functional safety serves the entire process by utilizing a single set of resources, such as PLCS. Normal safety requires dedicated resources for each process.

- In functional safety, keeping a record of all occurring hazards with time and date details is possible. In normal safety practices, keeping a record of occurring safety hazards is impossible.

IEC 62061

The International Electrotechnical Commission (IEC) defines functional safety planning and implementation. IEC prepares standards for electrical and electronics technologies.

IEC 62061 (safety of machinery—functional safety of safety-related electrical, electronic and programmable electronic control systems) is a standard for electrical and electronic safety systems to be used in machinery applications. It includes:

- Design guidelines for implementing functional safety

- Integrating functional safety with each process of a machinery

- Validating the safety system for its effectiveness

This standard does not cover systems that are not electrical or electronic in nature; for example, pneumatic, hydraulic, and mechanical systems. These systems are non-electrical and non-electronic and are not covered by IEC 62061.

Figure 2. IEC 62061 provides safety standards of machinery throughout different regions.

IEC 62061 Markets and Regions

IEC 62061 is implemented in different markets and regions as a part of providing a safe working environment. Let’s discuss implementation of IEC 62061 for a few of these markets and regions below.

United States of America

Standards including ones from The American National Standards Institute (ANSI) and the IEC are not enforceable in the United States.

Instead, the Occupational Safety and Health Administration (OSHA), a federal agency for enforcing safe work environments in the industrial and manufacturing domain, requires manufacturers to ensure a safe working environment for personnel during machine operation and servicing.

For ensuring the safety of machinery, OSHA refers to internationally recognized standards. It relies on IEC 62061 for the functional safety of machinery to provide a safe workplace for personnel in various industries.

European Region

The 2006/42/EC is the machine directive for the European market and deals with machinery and its various parts. Its main purpose is to ensure safety in machinery by utilizing different standards, technologies, and methods.

According to this directive, the machine must operate and be maintained without danger and risk of accident to personnel. This can be achieved by integrating safety concepts for eliminating hazards and providing necessary protective measures.

The above directive can be easily implemented by the European version of IEC 62061, known as EN 62061.

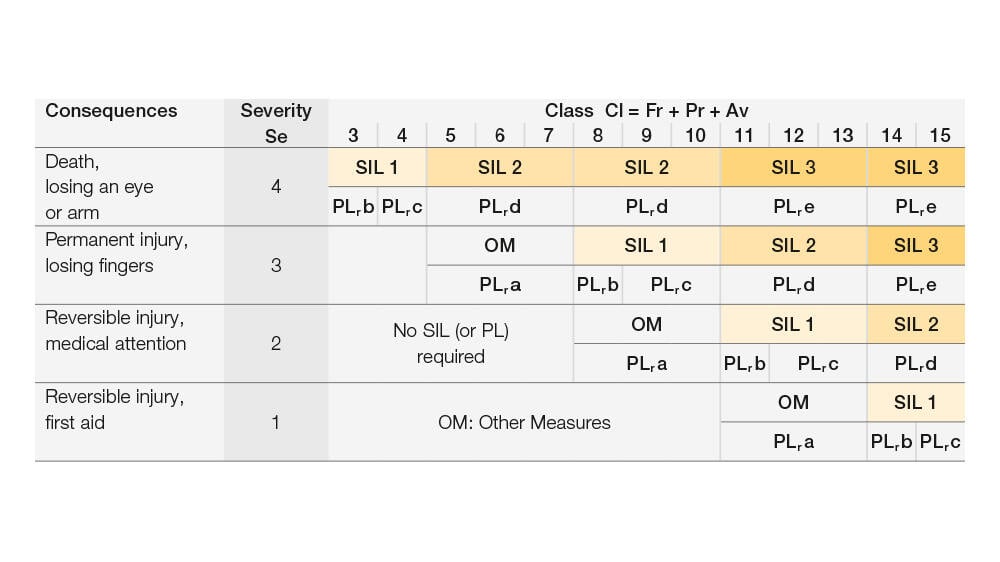

Figure 3. Safety Integrity Level (SIL) measures how well functional safety is implemented in machinery.

What is Safety Integrity Level (SIL)?

Safety Integrity Level (SIL) is a numerical method used by IEC 62061 and classifies the system’s ability to reduce risks. It measures how well functional safety is implemented in machinery.

For machinery, there are three levels. SIL 3 is the lowest level of integrity (meaning the system needs more functional safety measures), while SIL1 indicates a high level of integrity (meaning the system is capable of reducing the hazard when it occurs).

According to IEC 62061, SIL is calculated in the following steps:

- Severity of a hazardous event

- Frequency and duration of a personnel hazard

- Probability of hazard when exposed to it

- Possibility of limiting the effects of harm

Figure 4. Users and manufacturers are stakeholders responsible for implementing functional safety in machinery.

Implications of Safety Integrity Level

As mentioned above, SIL is used to classify a system’s ability to tackle different hazards. The SIL can be used by different stakeholders, such as users and manufacturers, to assess their systems. Some implications for the user and manufacturer are briefed below:

Implications for Users

The user is the primary stakeholder and is directly responsible for implementing functional safety in a machinery system. Otherwise, the user will have to suffer loss of material and face machine breakdown.

For functional safety, the user is responsible for:

- Defining relevant functional safety requirements accurately

- Verifying all the functional safety systems during supply or installation

- Participating in risk assessment performed by the manufacturer

Implications for Manufacturers

The manufacturer is the secondary stakeholder, and It is the responsibility of the manufacturer to ensure corresponding SIL requirements for the machinery they manufacture.

For functional safety, the manufacturer is responsible for:

- Performing a risk assessment during the design or development stage

- Implementing the results of risk assessment during the machine manufacturing stage

- Providing accurate and updated information to the machine buyer or user

Safe Machine Operations

Safety is among the top concerns for manufacturers, along with success and profitability. In order to properly create a safe environment for people and machines, the strategy begins with an assessment of functional safety and risks, then determines the implementation of proper safeguarding devices and tools.

Copyright Statement: The content of this website is intended for personal learning purposes only. If it infringes upon your copyright, please contact us for removal. Email: [email protected]