Whether using an industrial DIN-rail power supply or a linear supply for an audio application, these devices have the potential to fail. Although there can be several reasons, there are a few simple (and some not-so-simple) methods of testing a power supply for proper functionality.

Locating the faults in a system so often seem to return back to the simplest problems. When many parts of a system such as the sensors on a machine, or an entire PLC, go dead, that might indicate a faulty power supply, and the devices themselves are just fine.

Testing power supplies is usually a quick process, but without the right information, there are some results that can be misleading. Different types of power supplies also may provide differing abilities to be repaired. In many cases, once a faulty supply is identified, it’s much more efficient to simply replace the supply.

Method One: Testing with a Voltmeter

The first step is to test the supply with a voltmeter. Even this step can be tricky. Is it more effective to test the input terminals or the output? The answer may depend on the symptoms.

If we see that everything receiving power from the supply is turned ‘off’ and the supply is the primary suspect, you can check the input terminals first. If the input is properly receiving power, we can eliminate any problems from upstream. The problem must be limited to the supply or after. The meter must be set for measuring AC if the supply is powered from single or 3-phase power.

Figure 1. Most industrial power supplies use 1- or 3-phase input power. They also often have a voltage adjustment screw terminal, indicated here with ‘V ADJ’ with the curved arrow.

On the other hand, the output is the main factor that determines whether the devices will be receiving proper power. Testing the output terminals should yield something very close to the rated output voltage.

Industrial power supplies can sometimes be adjusted within a small range to fine-tune the output, but this is designed to compensate for loading effects. You should plan to adjust this at the very beginning of the installation. It should not be used to increase the voltage if it should suddenly drop one day after years in service.

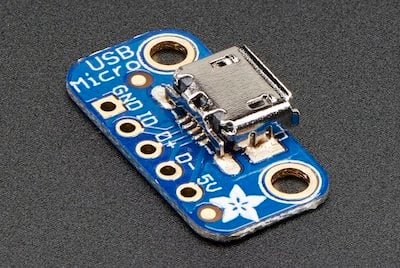

Sometimes testing the output is difficult, like on a phone charger USB cable. The terminals are extremely difficult to access. However, most of these tiny, inaccessible power supplies are very inexpensive, and replacement is the most obvious choice. If testing is very important, breakout boards can be purchased. These boards turn the tiny cable into a larger prototyping board with terminals than can be easily reached. I try to keep a couple of these types of boards around in my shop all the time.

Figure 2. Breakout board for testing supplies that do not have easily accessible terminals.

Method Two: Load Conditions

In the previous step, the testing was stated without respect to the load. Should it be connected when the test is performed, or not? The correct answer is both. First, the output should be tested with the load is disconnected (open-load voltage). If this voltage is correct, it means that the problem is probably located in an over-load, perhaps a short-circuit, downstream. If the open-load voltage has suddenly become too low or has turned off entirely, the power supply is probably the faulty component.

Again, be sure to test the input voltage before this step. If there is no input, then there should also be no expected output – the power supply is not the fault.

Once the open-load output is verified, then the load test should be completed. This is the real-world test since the open-load voltage isn’t actually what we are trying to determine. We really need to know if the power supply can still function when the devices are connected. Reconnect the load wiring and check to see what happens. It should be one of two scenarios:

The output voltage should reduce slightly. This is normal. If the current is being drawn through the load, the source voltage will always drop. However, the drop should not be significant, but it’s hard to tell how much this should be. All that can be said is “If the drop is too much, the power supply is failing and cannot keep up”. Reduce the load or replace the supply.

The output voltage may drop to zero. This is often seen in supply with overload protection like many industrial supplies. Too many load devices can pull too much power. Miswired or failed load wiring can create short circuits. In either case, if the load current is above the rated maximum, the output voltage will drop to zero. As soon as the load is removed, the voltage is restored. Find the source of the overload and remove it.

Method Three: Component Testing

Linear and switching power supplies both provide output voltages, but the method is quite different. When a switching supply is plugged in, many components inside are connected to the main line voltage. It is not advised to test or repair inside a switching supply unless you have the right tools and training.

Linear supplies tend to be more expensive, which means that repair might be more efficient. Even still, hours of testing and repair may be more costly than a whole new supply. The structure of a linear supply is fairly simple, so testing isn’t too bad.

First, a transformer (usually a large one) will have an input primary coil side with the supply AC voltage across it. Often there is a fuse in-line or even built into the transformer. This may be the overloaded component. The secondary coil voltage should be stated somewhere on the datasheet or the part sticker, and can also be measured as AC voltage.

Second, a bridge rectifier consists of two diodes always in series with each other at any time. The following components such as the capacitor will now show DC voltage. Be careful when testing capacitors as they can often store a dangerous charge, but the high impedance of a voltmeter creates a safe test for these relatively low voltage supplies. The section between the rectifier and the regulator can really only be correctly measured with an oscilloscope.

Figure 3. This linear power supply has a fuse (center) in-line with the transformer on the right side, clearly visible primary and secondary terminals, the bridge rectifier at the top, and a capacitor on the left. This type of supply would be quite expensive, and the ease of component replacement might make a favorable repair.

A voltage regulator is the final component before the load terminals. The output of the regulator should be a smooth, constant DC output, and can once again be tested with a DC voltmeter. Sometimes the output is an adjustable linear supply, like with a common benchtop double or triple-output supply. These regulators can also be tested, but there needs to be some method of calculating the correct output voltage or the measurement will be meaningless.

Summary

Testing power supplies usually does not include testing the internal components. For switching supplies, component-level testing is almost never done. First test the input voltage, then the open-load output, and finally the output with the load connected, and the source of the problem should be traceable. Finally, the fault can be corrected or the power supply replaced as required.

Copyright Statement: The content of this website is intended for personal learning purposes only. If it infringes upon your copyright, please contact us for removal. Email: [email protected]