Robots as a service (RaaS) can open the door to automation for small to mid-sized companies that are looking to automate a process without a large upfront capital investment.

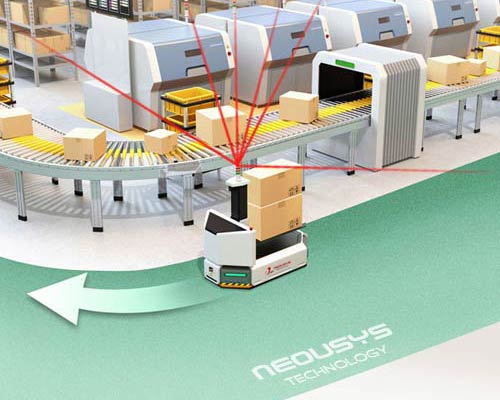

Figure 1. Autonomous guided vehicles (AGVs) are common in warehousing applications.

What is RaaS?

The software industry, particularly cloud computing, has been developing products as a service for many years, referring to this offering as ‘anything as a service’ (XaaS). Recently, the field of industrial robotics is trying to do the same thing. Robotics as a service, or RaaS, is essentially renting those industrial robots and the software that is required to program, track, and maintain the robots. This often includes regular software updates and hardware upgrades, hosting of program backups on a cloud server, and modular packages that can be added to the setup with minimal time investment from the customer when new features are added.

With a typical robot installation, there are many safety requirements that must be met and extensive PLC and robot programs that need to be written. Even with all these requirements, data collection is not always included and will require more programming and infrastructure. RaaS does open the door to automation for small to mid-sized companies that are looking to automate a process without a large capital investment.

Figure 2. AGVs often rely on cloud-based programming and data processing.

Standard Robot Installation

A standard industrial robot consists of the robot itself, a robot controller, a PLC (or another main controller), and a safety system. The robot controller and PLC will need to be programmed and integrated with the safety system. These robotic workcells take up a large amount of space on the factory floor, although the application of cobots has helped saved lost space in many cases. These systems are purpose-built and not very flexible, usually designed to handle a predefined selection of part types. If the part design is changed too much, the robot system will no longer be able to handle the part.

RaaS Application

Where the RaaS framework really shines is with collaborative robots (cobots). With a cobot, you don’t need large expensive safety systems, they complete tasks alongside human operators without guarding. With this flexibility, a generic cobot system can be designed offsite and then implemented in virtually any application. A great example is in the warehouse industry where products need to be moved from a storage racking system to a conveyor. This work would normally be done by somebody on a forklift, but what if you could use a small robot to lift the required rack from the storage place and transport it to the conveyor without the need for human interaction? With this style of cobot, it would need sensors to read and interpret the real world such as somebody crossing the robot’s path, finding the required product on a shelf, or even the number of remaining products on that shelf. With all of this data being digitized, it can then be processed and stored with cloud software. To implement this kind of system a large upfront capital investment would need to be made, and it may take years for a smaller company to see a return on that investment.

Companies Offering RaaS

While this service is still new, many of the large software companies – including Amazon, Google, and Microsoft – are all in different stages of developing a RaaS solution. Even with these large companies having a vested interest in RaaS, there are very few companies offering both the RaaS hardware and application solution. Doing an internet search produces articles (much like this one you are currently reading) explaining the concept and a few companies offering a software-only solution.

Figure 3. Amazon Web Services (AWS) is a leading provider of many products ‘as a service’ – not just robotics.

Amazon AWS RoboMaker

Amazon’s RaaS solution is an online simulator that allows developers and designers to virtually simulate an application without investing in the actual hardware. Programming robots is unlike creating computer or mobile applications, you can’t test all of the code easily without an actual robot. Having robot hardware sitting in an R&D room, waiting to be used for testing is an expensive investment. Amazon has built on to their AWS Cloud 9 software by adding the capability of creating virtual worlds that robots can move around in. This virtual world can be customized to replicate a real-world environment in which a robot can be tested. Developers can use this service to find integrate their code, and mechanical designers can use it to find flaws in sensor placement or physical changes that may need to be made before the robot is mass-produced.

Figure 4. Google Cloud is another leader in the cloud services space.

Google Cloud Robotics Platform

Using cobots in the warehouse industry is nothing new, automated warehouses have become more popular with the rise of online shopping. The Google cloud robotics platform adds to the function of warehouse robots by offering all the software required to program, track, and collect data in a cloud-based solution. A typical storage and retrieval cobot would need high-end computer architecture and an IT department, to track and collect data on the cobots running around your warehouse. What Google is offering as a service is all of this capability on their already popular cloud platform. This will allow for easy migration of data into other Google offerings like Cloud Bigtable and Cloud AutoML. The overall theory is to offer an open-source software service that makes integration and maintaining of storage and retrieval cobots faster and easier.

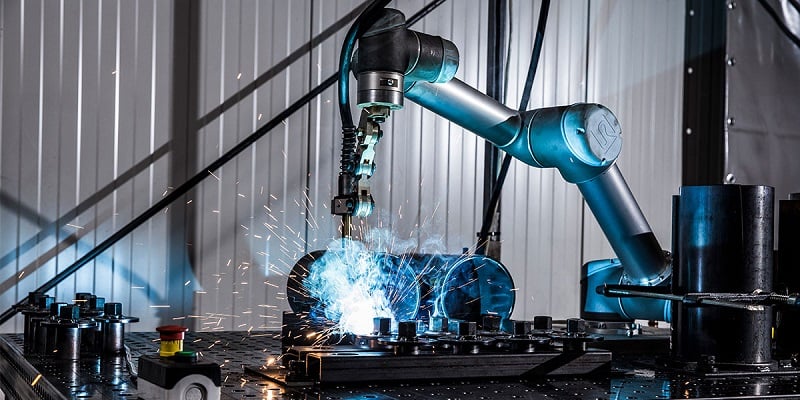

Figure 5. Smaller companies may consider RaaS as a solution for cobot fabrication enhancement.

Conclusion

Robot installations can be expensive and take a long time to complete depending on the size of the application. For small to mid-sized companies, this expense can be a deal-breaker to the automation world. By offering the hardware and software as a service, the cost of the automation comes out of the operating budget instead of the capital budget. The companies offering RaaS seem to be more focused on the software and cloud functionality rather than the hardware of the robot itself, but robot installations can be highly customized and do not suit every application, so it is most likely to require the expertise of an integration firm.

The cobot and storage and retrieval product lines will benefit the most from a RaaS solution as they don’t require the safety or control overhead. Cobot arms are being used more frequently in welding applications. If you are a small company that has recently had an influx of orders, rolling in a cobot to help with the welding application might be a good fit for a RaaS installation. The same is true for a mid-sized online retailer that has recently seen a rise in online orders. By using a RaaS solution they can meet the new demand without a large capital investment.

Copyright Statement: The content of this website is intended for personal learning purposes only. If it infringes upon your copyright, please contact us for removal. Email: [email protected]