We know what a circuit breaker is meant to do: stop the flow of electricity in case of a fault or failure. But just like fuses, breakers and overloads respond differently depending on the load.

Circuit breakers and motor overloads are designed to open a circuit under dangerous overcurrent conditions. This is often less about the safety of the operators and technicians, rather, it’s about preventing circuit damage and fires from overheating.

Difference Between Breakers and Overloads

The task is the same, but the specific application is different. An overload is a specific kind of circuit breaker, meant for protecting motors, while a circuit breaker is a more general branch protection device covering all kinds of loads.

The reason that this distinction is important is because a motor is a very inductive load, that is, it converts energy not through the resistance of the coils (which is actually wasted heat) but instead through the induced magnetic field that moves the rotor. The overload, then, it purpose-built to expect a highly inductive load, which behaves differently from one that is resistive.

R and L Circuits and Loads

It’s important to understand how resistance and inductance are different. For many loads (lights, heaters, etc., as you find in a normal house), the amount of voltage applied will yield a certain amount of current at any time. Lower the resistance, and the current will rise. Short circuits or too many connected appliances will cause the current to rise too high and trip the breaker. For this reason, household breakers are not rated according to the type of load, the current and mounting style are really the main parameters.

Inside an industrial facility, every motor, solenoid, relay, and contactor moves its load by means of an electromagnetic coil. Motors present a particular challenge. The back effect (force resisting the flow of current) is lower when the motor is spinning slower than the source frequency, in other words, when it’s accelerating to full speed. Since the back emf is lower, the reactance of the circuit is also lower, and the current is higher. Motor inrush current is always higher than full-load current, and it changes depending on the size and acceleration speed of the motor.

For the resistive portion of the coils, this current will always be a fixed amount, but the reactive part of the current will be significantly higher for a short duration.

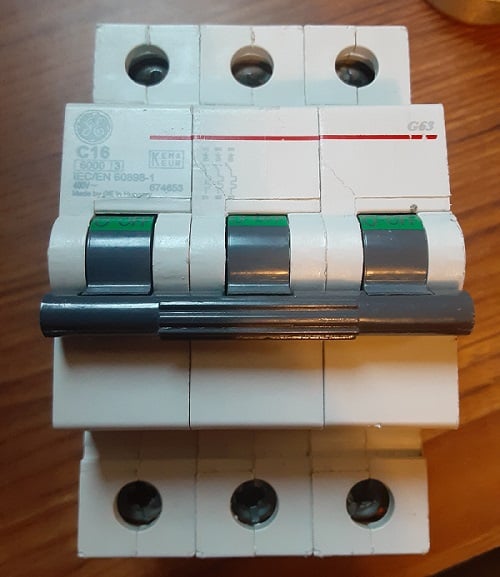

Figure 1. A GE circuit breaker labeled with C16, meaning a C-curve breaker with a 16-ampere rating.

Circuit Breaker Curves

The curve of a circuit breaker is the graphical drawing of the profile that determines how much current will be allowed, and for how much time, for both AC and DC portions of the load current.

Common curves for industrial circuit breakers are B, C, and D, and the conditions of design and use are dictated by UL 489. Sometimes, other categories are listed, such as Z, S, and K. Each curve profile has certain intended applications, with the B, C, and D being quite common for DIN-rail miniature breakers.

The breakers have two unique trip components inside, a thermal and a magnetic stage. The magnetic trip stage will respond instantly to large overcurrent conditions, and these are usually set to trip at a higher current than what the load device should normally allow (often much higher).

The thermal trip stage requires a bimetallic strip to be heated to a certain temperature to cause the tripping. This takes more time, so it is immune to the instant in-rush current, instead responding to long-term, steady-state overcurrent issues which rise only slightly above the running current.

The table below lists the magnetic overcurrent rating, that is, the level at which the circuit breaker will trip if the inrush current exceeds a certain multiple of the breaker standard rating.

| Trip Class | Short-Term Overcurrent | Purpose |

| B | 3x-5x | Resistive |

| C | 5x-10x | Med Inductive |

| D | 10x-20x | High Inductive |

| S | 13x-17x | High Inductive |

| Z | 2x-3x | Semiconductors |

| K | 10x-14x | High Inductive |

How Fast Does It Trip?

The words ‘short-term’ and ‘long-term’ are quite vague. The magnetic trip action will respond the most quickly. The higher the overcurrent level, like the D and S-curves, the faster the response, at less than 1 second.

For the lower current curves, like B and Z, the trip time may be a bit longer, up to nearly 10 seconds and 30 seconds at a maximum, respectively. However, they are likely to open much more quickly than this maximum time value.

For the longer-term thermal trip stage, the time is progressively longer depending on the level of excess current. If the current is only barely above the rated trip value, the breaker may take well over an hour to trip. However, the design requirements would prohibit the selection of a breaker that is nearly equal to the rated load current.

Figure 2. Overload relay displaying the ‘Class 10’ rating.

Motor Overload Relays

Now that we understand trip curves, the idea of an overload trip class is quite similar.

Overload trip classes appear most often as class 10, 20, or 30. These numbers relate to the number of seconds that the overload will maintain contact if an excessive inrush current is experienced.

If the current is 6x the full-load amps of the overcurrent relay, the class 10 device will trip after 10 seconds, class 20 after 20 seconds, and class 30 after 30 seconds.

The design choice is made based on the expectation of the motor. Some motor situations can easily survive excessive current for a few seconds at startup, and it’s not unexpected, so it would be a nuisance to have to resent breakers constantly to start a process.

Overcurrent: Is It OK?

Just because the amount of electricity in a circuit exceeds the breaker level, that’s not always a problem. Be sure to know what kind of device you’re using, and make the correct judgment according to the machine design and local electrical regulations, and you won’t need to worry about constant nuisance tripping of breakers.

Copyright Statement: The content of this website is intended for personal learning purposes only. If it infringes upon your copyright, please contact us for removal. Email: [email protected]