In industry, pressure can be used in various sectors for safety and containment. Before diving into specific applications, let’s learn about the types of pressure measurements.

Various pressure measurements are used in the industrial environment. Pressure is one of the most critical process variables from a manufacturing and a safety perspective. Pressurized gases are used to move materials, drive reactions, provide inert environments, remove hazardous substances, and many other critical tasks.

Pressure Measurement Overview

From physics class, pressure is merely the applied force divided over an area. A magician can lay on a bed of nails and be uninjured because his weight is spread out over many nails. If the same magician steps on a single nail, he will be injured because the pressure is much greater in the second case; his entire weight is applied to a much smaller area.

Figure 1. An industrial engineer checking a condenser water pump gauge.

Pressure measurements are most commonly applied to “fluids,” where a fluid is either a liquid or a gas. While liquids and gases behave differently, some of the concepts are the same for taking pressure measurements. Pressure gauges specify what substances they can detect. For instance, the pressure gauge for measuring compressed air cannot be used for measuring water.

Too much pressure can cause vessels to rupture, which can cause death, injury, and significant damage to infrastructure. Too little pressure, in some cases, can lead to the same; for example, suppose reactive chemicals are stored under an “argon blanket” where argon flows into the room to prevent the reaction.

Engineers and technicians must understand how to keep pressure within tolerances. Therefore, they must have accurate pressure measurements to base control decisions.

The first question to consider is, “What type of pressure measurements are required?” There are absolute, gauge, and differential pressure measurements.

Types of Pressure Measurements

Absolute Pressure

Absolute pressure is the pressure a fluid exerts against a surface. It includes the fluid pressure, plus any pressure applied by the atmosphere that is also pushing down on the sensor.

Gauge Pressure vs. Atmospheric Pressure

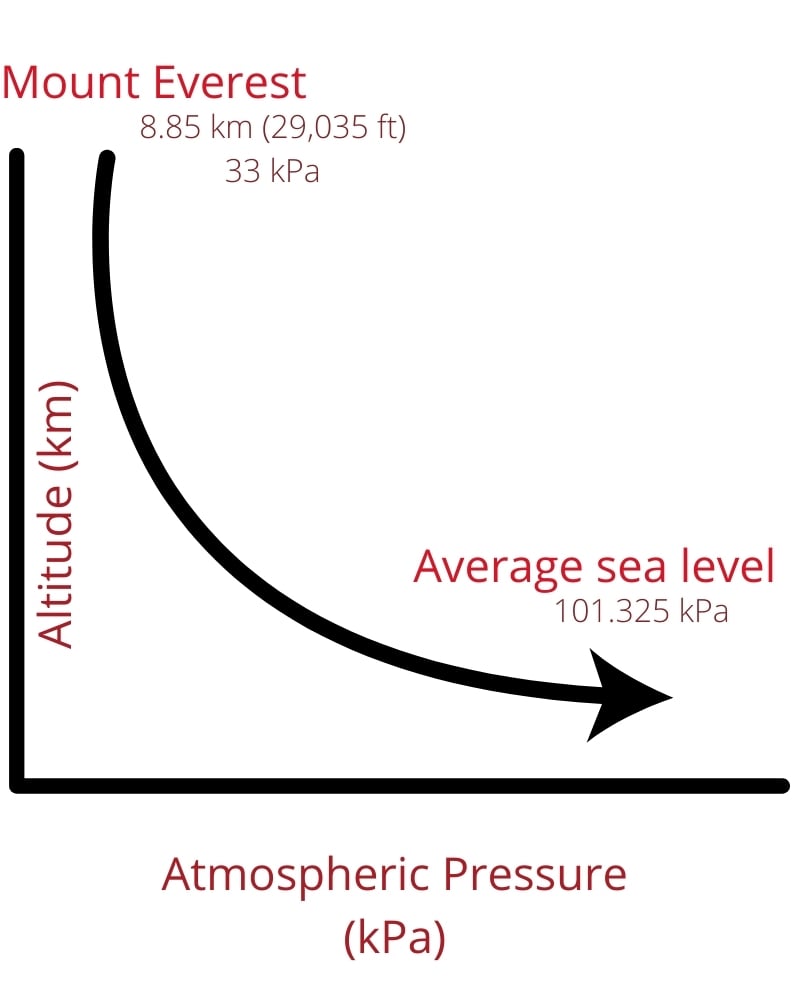

Gauge pressure is a measurement against the atmospheric pressure. Atmospheric pressure (at sea level) is around 101.325 kPa (14.696 psi), and this pressure is applied to all objects—just from the weight of the atmosphere pushing toward the center of the Earth.

Atmospheric pressure creates some confusion in pressure measurements. For example, the surface of a settling pond (under no industrial or forced pressure) at sea level is experiencing 101.325 kPa (14.696 psi) of absolute pressure. This measurement may not be of much value from an industrial perspective, as no industrial force (from pumps, for example) is being applied to this surface.

Instead, it is sometimes more useful to refer to “gauge pressure,” which is simply the absolute pressure minus the pressure due to the atmosphere. In this case, the surface of the settling pond would be 0 kPa gauge pressure.

Figure 2. An infographic showing how atmospheric pressure changes depending on altitude.

In terms of actual hardware, the matter is even muddier. Some gauge pressure sensors simply subtract out atmospheric pressure mathematically, and others are open to the atmosphere to compare the actual atmospheric pressure to the process.

At sea level, in stable weather conditions, there is no difference between these methods. However, if the gauge is used at higher altitudes or in various weather conditions, subtracting the standard pressure may not accurately represent the conditions.

It is worth comparing the sensor to known standards under several weather conditions to see how the particular sensor operates. Also, to differentiate between absolute and gauge pressure, gauge pressure is often specified with a “g,” such as “38.25 psig” for gauge measurements and “38.25 psi” for absolute measurements.

Differential Pressure

Differential pressure measurements are a way to measure pressure relative to another fluid. Gauge pressure, as discussed above, is a special application of differential pressure measurement, where a process pressure is measured against atmospheric pressure.

Besides gauge pressure, differential pressure measurements are useful for comparing two pieces of a process. For example, in a dairy, certain parts of the process must be pressurized to avoid contamination moving backward into the milk. If the good milk is at a higher pressure, then even if a valve leaks, contamination will not flow from a lower pressure area to a higher pressure area.

Figure 3. Differential pressure between processing units is frequently used in food processing to prevent material backflow, leading to contamination, or extending residence time past safe limits.

This is also used in semiconductor and medical cleanrooms. The cleanroom is at higher pressure, helping to keep dust and debris out of the room, even when someone enters the cleanroom. In all of these cases, the gauge pressure of one part of the process is not as important as its pressure relative to another part of the process.

Differential pressure measurements can also be used in other applications besides simply measuring pressure. In our next differential pressure article, we will chat about alternate uses in the industrial sector.

Copyright Statement: The content of this website is intended for personal learning purposes only. If it infringes upon your copyright, please contact us for removal. Email: [email protected]