Sensors with timer functions advance modern automation systems, enhancing the precision and flexibility of in-process controls to ease the strict requirement for an external, clock-based logic CPU.

Modern, sophisticated sensors often include integrated timing capabilities, allowing for precise coordination of actions based on input signals. These sensors offer a range of functionalities, including on delay, off delay, combined on/off delay, and one-shot triggers.

It’s important to understand how to make use of these functions, but we must also answer one burning question: if PLCs and microcontrollers are so easy to use, why would we ever want a timer inside the sensor itself?

Timer Functions

To begin, let’s investigate the definitions of the various basic timer functions.

On Delay

A sensor with an “on delay” function doesn’t immediately trigger an action when it detects something. Instead, there is a delay before the action starts. It’s similar to pressing a pause button, and then waiting for a few moments before resuming play. For example, if a sensor with an “on delay” function detects an item on a conveyor belt, the belt won’t start moving immediately. It waits a few seconds (or however long it’s set for) before moving the item along the production line. This delay helps control the timing of actions in automated processes, ensuring they happen at just the right moment.

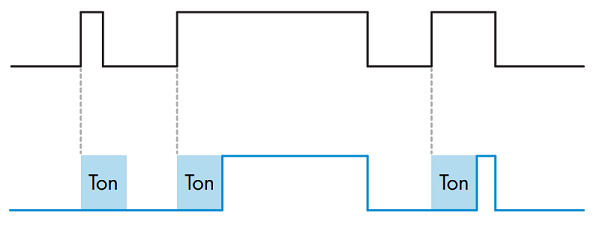

The image below illustrates two different “on delay” scenarios: A rising (black) input pulse that doesn’t last as long as the Ton time, and so the output (blue) signal never energizes. The final two signals last sufficiently long to energize the blue signal until the input goes false.

Figure 1. On delay signal examples.

Off Delay

A sensor’s “off delay” function isn’t exactly the opposite of an on delay as the name might imply. Instead of delaying the start of an action, it delays turning something off after the sensor stops detecting. For example, imagine a motion sensor in a room. When it stops sensing movement, instead of immediately turning off the lights, there’s a delay before they go out. In manufacturing, the machinery won’t stop immediately if a sensor with an off delay function detects an object leaving a specific area. Instead, it runs for a set period, allowing for a smooth transition or completion of a task before shutting down, like a cooling fan or a ‘motor running’ warning light.

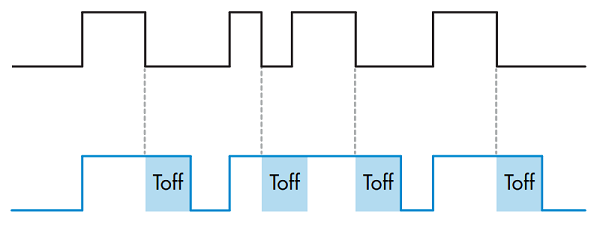

The image below illustrates two different “off delay” scenarios: The input pulse in the first example remains low beyond the Toff time, and so the output (blue) signal also goes low. The second returns high before the Toff time is reached, so the output never goes low. In both of the final signal transitions, the Toff time is reached, so the final does become low.

Figure 2. “Off delay” timer functionality.

On/Off Delay

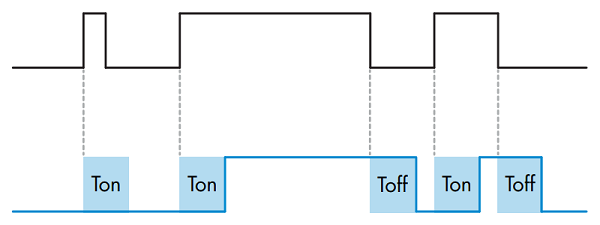

The “on and off delay” function in a sensor combines the features of both an “on delay” and an “off delay” to create a true delay before any kind of output event, either on or off.

When the sensor initially detects the object, there is a delay before the output starts, similar to an “on delay.” Then, after the sensor stops detecting, there is another delay before the action stops, just like an “off delay.”

When a sensor with an “on and off delay” function is paired with a conveyor belt, there will be a delay before the belt starts moving, then a second delay before the belt stops.

Figure 3. “On and Off Delay” timer function.

One-Shot; Leading and Trailing Edge

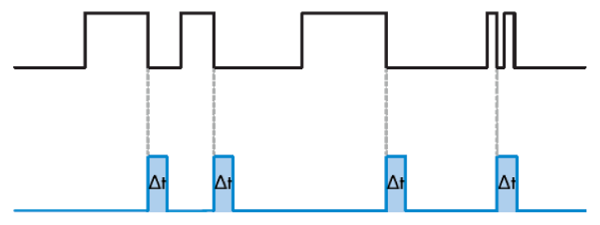

A “one-shot” function in a sensor is like a quick burst of action in response to a trigger. There are two types: “leading edge” and “trailing edge” (sometimes these are called “rising edge” and “falling edge”). These may be considered a logic function just as much as timing.

For a leading edge pulse, the short output pulse occurs immediately when the input is energized, but only once, regardless of how long you hold the button. A trailing edge produces the output action just as you release the input signal. Nothing happens as you hold the button (or sensor signal), but as soon as you let go, the pulse is produced.

Imagine you have a sensor with a one-shot function set to leading edge. When an item passes the sensor field, it triggers a quick burst of action, such as activating a pneumatic cylinder to push it into the next production stage. With “trailing edge,” the action would occur as soon as the item passes the sensor, but only once it’s clear of its range. These one-shot functions are helpful for precise, single-action tasks in automated processes.

Figure 4. One-shot (trailing edge) timer function.

Why not Just Use a PLC?

It is true that as PLCs and microcontrollers become smaller and cheaper, the need for dedicated timer relays and sensor modules becomes less frequent. Still, there are a few reasons that timer modules can be used to ease the burden on a controlled system.

Improved Reliability

Distributing timing functions across sensors and the PLC can enhance the reliability of industrial automation systems. The system gains redundancy by assigning timing tasks to sensors with built-in timer functions. In a PLC failure, sensors with autonomous timer functions can continue operating independently, ensuring critical timing tasks are still performed.

Reduced PLC Programming Complexity

Transferring logic and timing functions to sensors can significantly reduce the complexity of PLC programming. Distributing logic and timing responsibilities across sensors and the PLC makes troubleshooting simple, as the source of issues can be isolated more easily. Also, with fewer logic and timing functions to manage in the PLC, programmers can focus on higher-level control strategies.

Simpler Installation

Using sensors with built-in timer functions offers a simple approach to installation compared to configuring a PLC system for timing operations. With sensors, the installation process is simple:

- Mount them in the desired location.

- Connect them to the power source and other controls.

- Configure their parameters using user-friendly interfaces.

This simplicity reduces installation time and complexity, allowing faster deployment and integration into industrial automation systems. Additionally, the intuitive nature of sensor interfaces simplifies parameter adjustment, enabling operators to fine-tune timing settings easily.

Applications of Sensor-Integrated Timers

Conveyor Control

Precise timing is crucial for smooth manufacturing operations along conveyor belts. Sensors equipped with on-delay timer functions could be vital in controlling the start of conveyor belts. When an item is detected by a sensor positioned at the beginning of the conveyor belt, an on-delay timer is initiated. This timer ensures a delay before the conveyor belt starts moving, allowing time for the item to be correctly positioned before transportation begins.

Palletizing in Warehouse Logistics

Automated palletizing systems could be equipped with both on and off delay timer sensors to optimize the palletizing process. When the sensor detects a product, an on delay timer starts, allowing time for the product to be properly positioned for palletizing. After the product is palletized, an off delay timer ensures that the palletizing mechanism continues to operate for a set duration to complete the palletizing process before shutting down.

Robotic Welding in Automotive Manufacturing

Robotic welding is crucial for assembling vehicle components. Sensors with one-shot timer functions enable precise control over the timing of welding operations. When a component is in position for welding, sensors detect its presence and trigger a one-shot timer to generate a single pulse. This pulse activates the welding robot, which performs a single weld operation before waiting for the next trigger signal.

Packaging Machine Control

Packaging machines wrap and prepare products to be easily distributed and sold in food processing plants. Sensors with a one-shot timer function could ensure accurate timing of packaging operations. When a product is detected by sensors, a one-shot timer (trailing edge) is activated. This timer generates a pulse after the product has passed the sensor, triggering the packaging machine to dispense packaging material for the following product.

In these industrial automation applications, sensors with timer functions enhance precision, efficiency, and reliability, contributing to optimized operations and product quality.

Copyright Statement: The content of this website is intended for personal learning purposes only. If it infringes upon your copyright, please contact us for removal. Email: [email protected]